Fixtures

Targeting Fixtures

Inspection Fixtures

Straightening Fixtures

Machining Fixtures

Pressure Test Fixtures

High-Quality Fixtures

Efficiency and Accuracy

At TMI, we understand the pivotal role fixtures play in high-quality casting production and inspection. Using cutting-edge CAD/CAM systems, we meticulously design and manufacture fixtures to ensure precision. With full 3D model approval before production, we customize fixtures to meet specific needs. Employing advanced CNC machining techniques and precision welding, we deliver fixtures to exact specifications, ensuring superior performance and reliability.

- Customized Design

- Precision Machining

- Industry Expertise

- Advanced Inspection

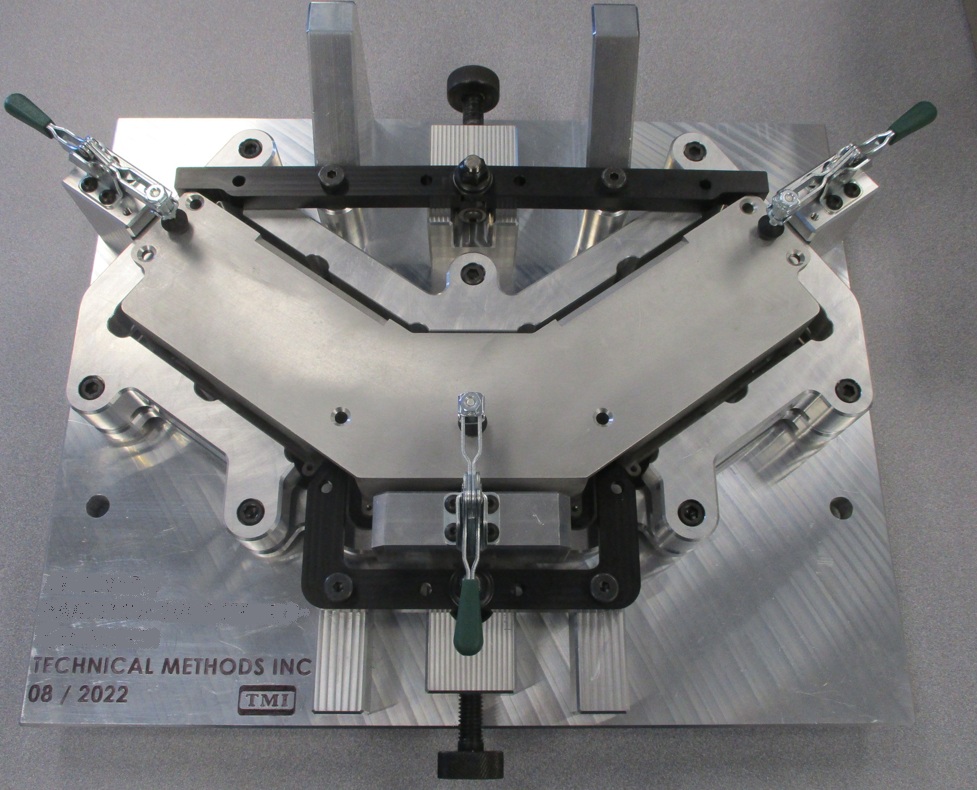

Target Fixtures

Post-Processing

Our target fixtures are designed around your targeting work instructions. Whether you’re using templates, sight glasses, or dials to establish your targeting points, we have designed and manufactured it all. All target fixtures come with associated toolkits and rollovers needed to perform your operation as efficiently as possible.

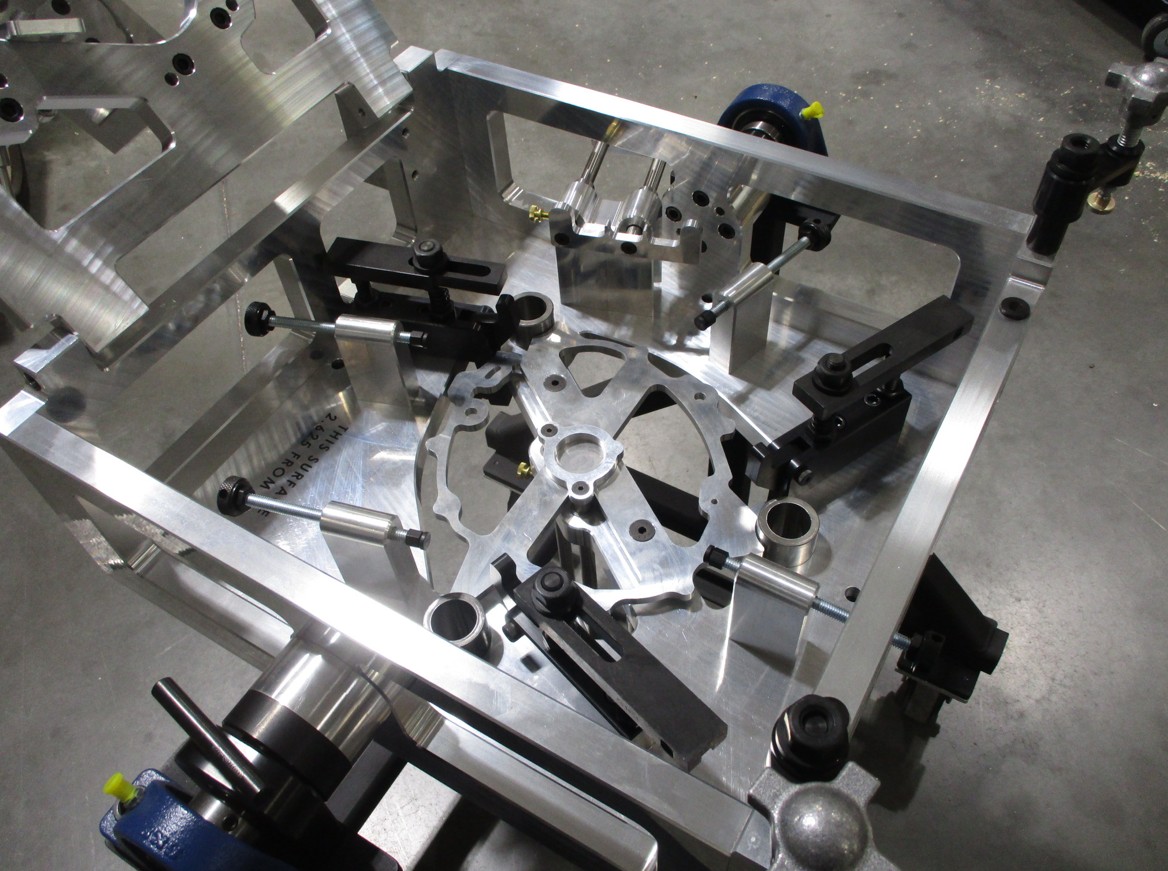

Inspection Fixtures

Dimensional Tolerance

Our inspection fixtures help you quickly identify non-conforming features on your parts. Drawing from industry best practices, we will develop the approach, design the fixture, and allow you to review/approve the project before we machine and assemble your fixture.

Heat Treat Fixtures

Distortion Prevention

A well-designed heat treat fixture keeps parts stable through the entire cycle, reducing warping, maintaining tolerances, and cutting down on costly rework. Our team engineers fixtures specific to your geometry and process, helping you achieve consistent results, higher yields, and reliable part performance.

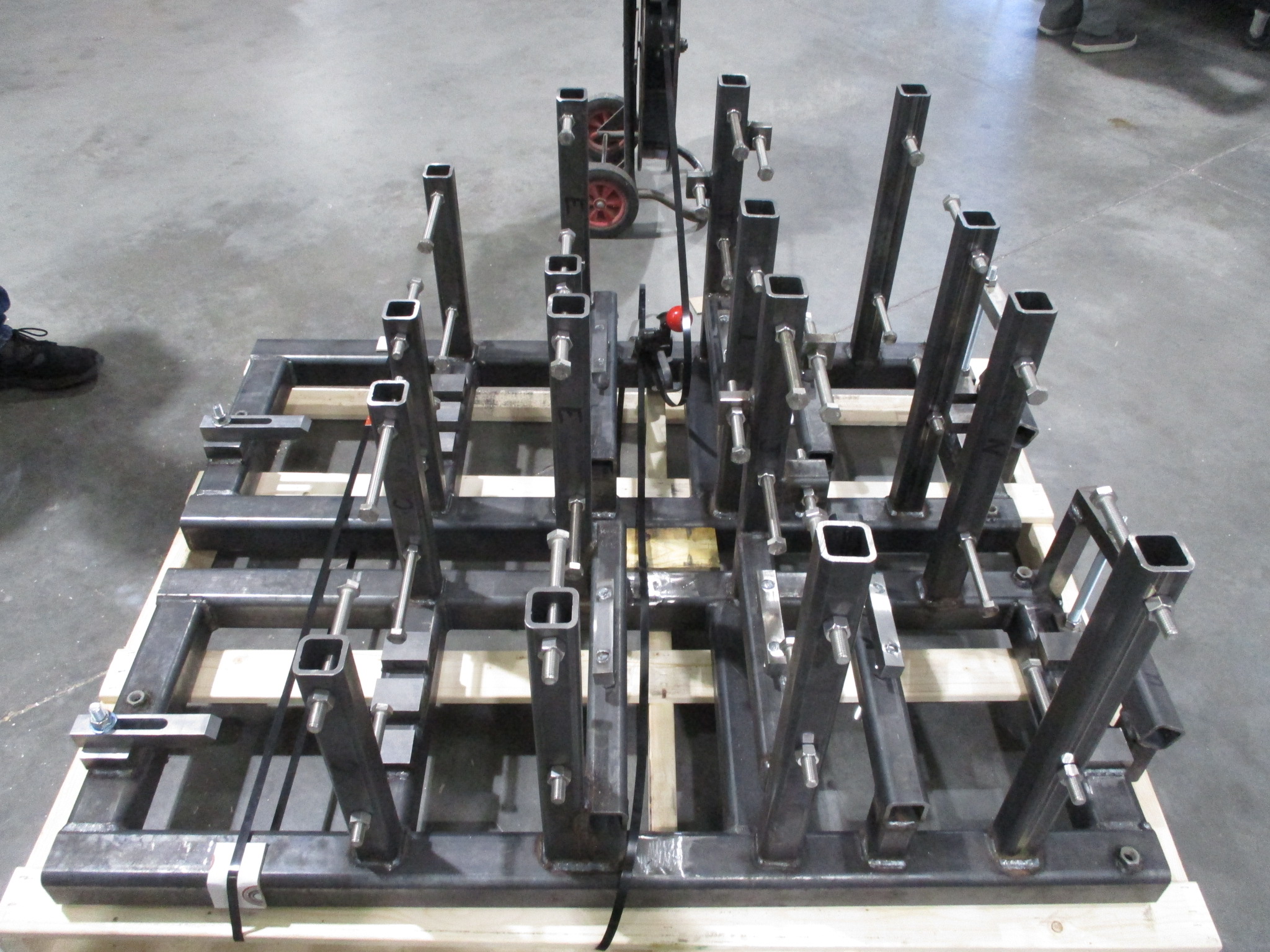

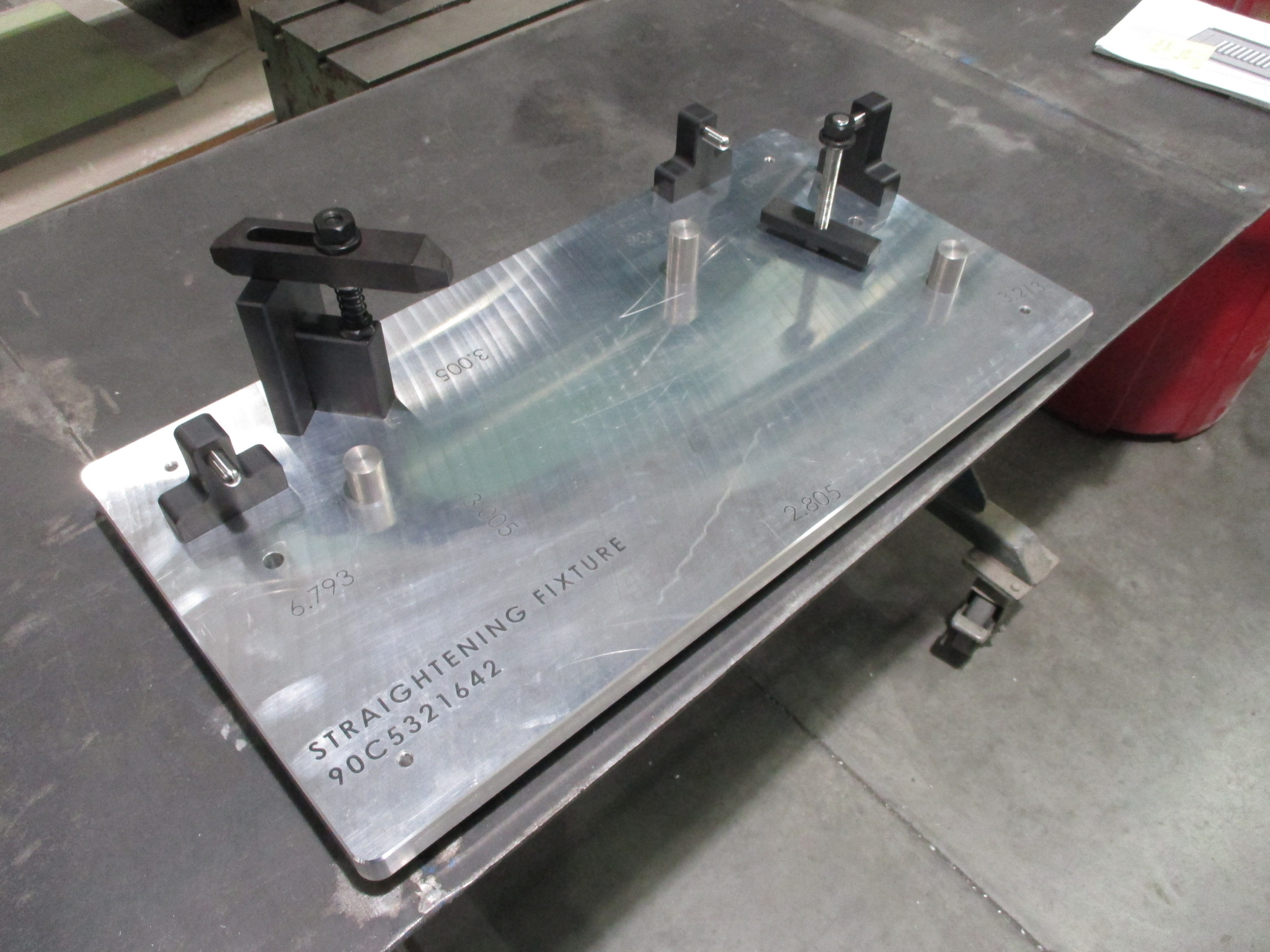

Straightening Fixtures

The Difference in Scrap

In aerospace castings, even minor distortion during pouring or heat treatment can push critical features out of tolerance, leading to costly scrap or rework. A dedicated straightening fixture provides a repeatable, controlled method to bring parts back into spec while preserving structural integrity.

TMI's Fixtures Advantages

TMI’s fixtures are designed with your needs in mind. Our design experts understand what goes into delivering a quality casting and will design fixtures to ensure all critical dimensions are accounted for. We machine our components using the latest CAD/CAM software, a modern fleet of Haas CNC mills, and advanced inspection equipment to ensure we consistently meet the highest industry tolerances.

Industry Expertise

Our fixtures are designed by engineers with decades of experience in the casting industry. We design fixtures to keep your scrap rates low.

Modern Technology

Fixture designs are built using the latest versions of CAD/CAM software and a modernized fleet of Haas CNC vertical mills to achieve the tightest tolerances.

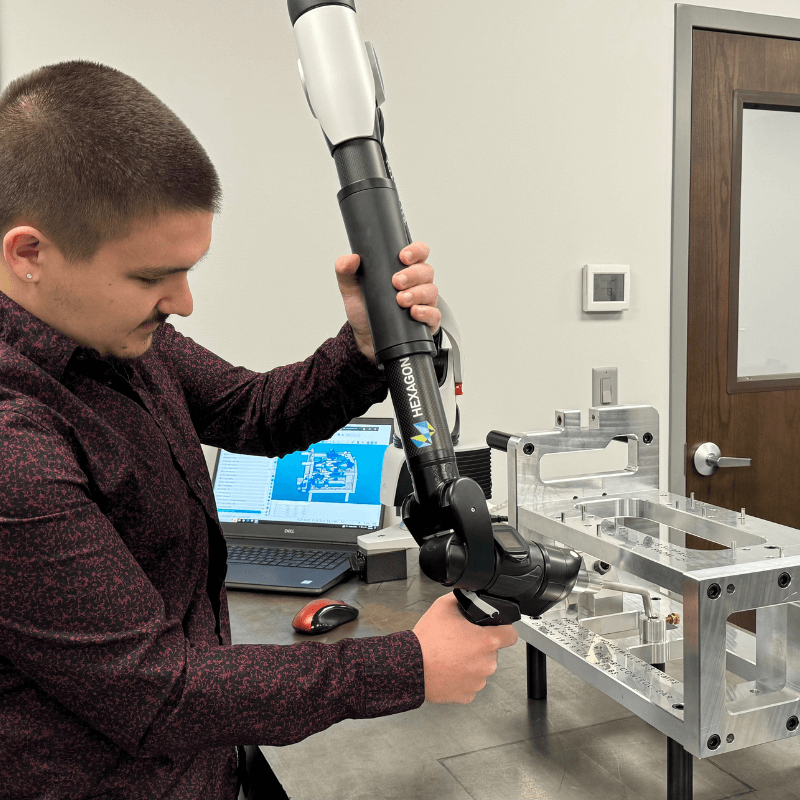

Advanced Inspection

Assembled fixtures are scanned using our 7-Axis Hexagon Arm to ensure every fixture meets our intended design tolerances prior to being shipped.