Inspection Services

Blueline Layouts

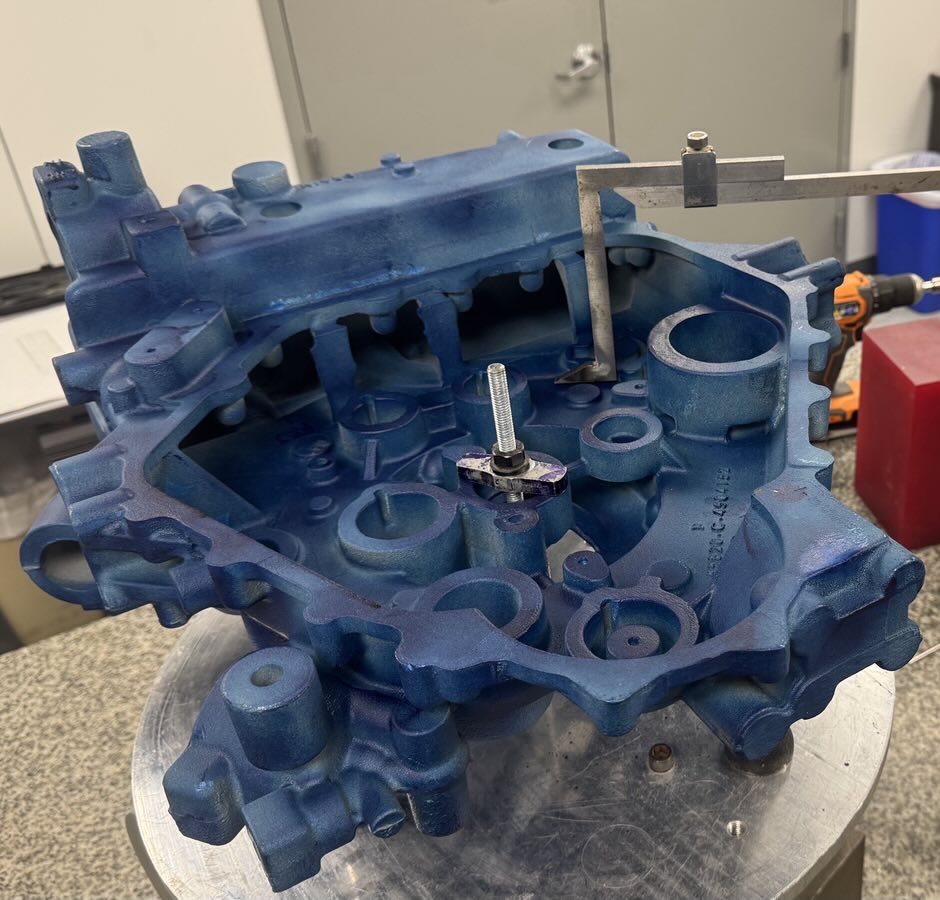

Layout Scan

Blue-Line Layout

A Proven Process for FAI

Whether you are performing a first article inspection (FAI) or requalifying an idle tool, we offer advanced services to get your parts into production. Our layout inspection process utilizes proven methods to measure, verify, and document every dimension of your part, ensuring it meets exact specifications and industry standards.

- Industry Experience

- Calibrated Tooling

- Proven Methods

- Detailed Reports

TMI's Layout Inspection Advantages

Proven Methods

TMI utilizes a time-tested layout process that involves dissecting castings to analyze their features on a rotary table. This process allows us to familiarize ourselves with castings in ways modern techniques cannot offer.

Industry Experience

Our engineers bring decades worth of layout inspection experience. This experience allows us to collaborate with our customers to focus on features that are critical to qualifying your parts for flight.

Detailed Reporting

Upon completion of our layout inspection, we provide detailed reports outlining casting performance relative to each specification in the blueprint.

Proven Success

At TMI, our success in the aerospace and defense industry has withstood the test of time. With a commitment to excellence, our products and services set our customers up for success around the clock. Our precision and innovation consistently deliver outstanding results, making us a partner you can rely on.