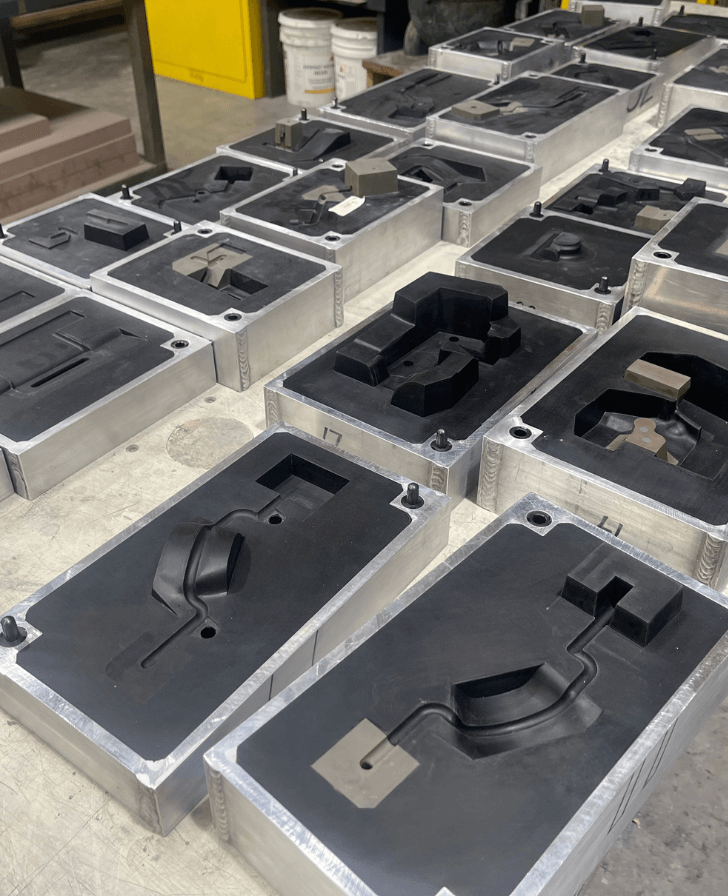

Production Molds

Urethane Cast Core Boxes

Higher Investment, Built to Last

We pride ourselves on delivering top-tier dry sand tooling tailored to meet the specific needs of the aerospace industry. With decades of experience and a dedicated team of professionals, we ensure that every mold we create stands up to rigorous standards of quality and precision.

- Cope/Drag

- Core boxes

- Core Drier Boards

- Chills & Chill Patterns

- Rollovers

- Assembly Gauges

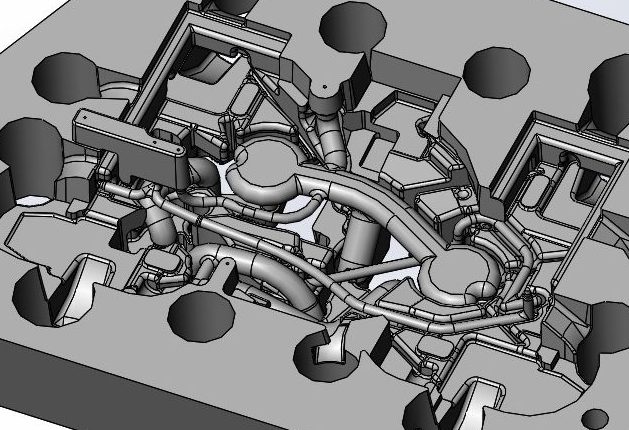

Hybrid Tooling

Lower Investment, Faster Time to Market

Hybrid tooling reduces your initial investment in production tooling by replacing urethane core boxes with sand-printed cores. These tools feature a traditional cope and drag, but are engineered specifically to accommodate a sand-printed core assembly. This approach not only lowers up-front tooling costs but can also accelerate time-to-market when sand-printing cores is a viable option.

- Cope/Drag

- Sand Core Design Files

- Machined Chills

- Rollovers

- Ball Gauges

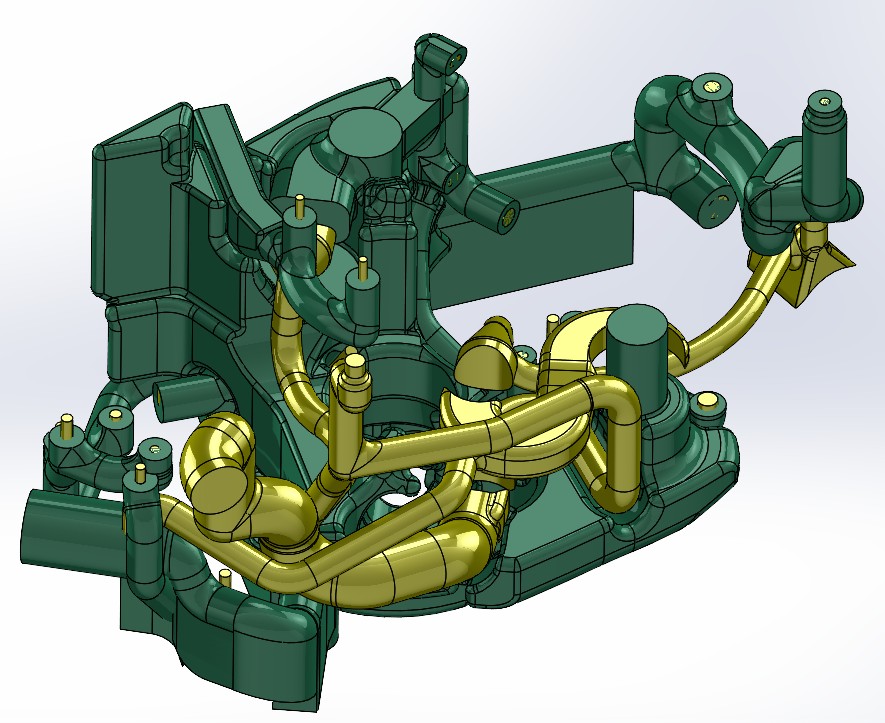

Engineering Services

Mold Design

Need support designing a mold for sand printing? Looking to translate a blueprint into a CAD model? Evaluating DFM considerations to optimize your part design?

Our engineering team brings deep experience in tooling design, CAD modeling, and manufacturability analysis. We’ll work with you to ensure your project meets performance, cost, and lead time requirements. Contact us to discuss your design challenges.

- Sand Print Design Files

- Design for Manufacturability

- Blueprint-to-CAD

Proven Success

Our 32-year legacy supporting the aerospace and defense industry has withstood the test of time. With a commitment to excellence, our products and services set our customers up for success around the clock. Our attention-to-detail and continual quest for improvement consistently deliver outstanding results.